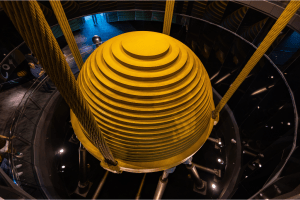

Vibration is a common phenomenon in industrial facilities and can have a significant impact on worker health, safety, and the budget of a mining facility. This article will explore the hidden risks of vibration. Here’s why our engineers draw on standards such as AS 2670.1-2001 and AS ISO 2631.2:2014. What produces vibration Vibration in industrial facilities can originate from various sources, including machinery, wind, tremors, and industrial processes. The perception of vibrations varies significantly among individuals. According to AS 2670.1-2001, fifty percent of alert, fit persons can just detect vibrations with a peak magnitude of 0.015 m/s2. The perception threshold decreases slightly with increases in vibration duration up to one second and very little with further increases in duration. However, the sensation produced by vibration at magnitudes above the threshold may continue to increase. Health effects of vibration A moderate exposure to vibration can interfere with comfort and daily activities and can potentially lead to a decrease in the quality of life. The sensations caused by vibration, such as discomfort or annoyance, can also affect the overall well-being of individuals. In some cases, vibration can even lead to motion sickness, causing further discomfort and other related symptoms. More seriously, long exposure may present a health and safety risk, potentially causing pathological damage or physiological changes within the body. Vibration syndrome, also known as vibration white finger and as Raynaud’s phenomenon, has adverse circulatory and neural effects on the fingers. Over time, this blanching of the fingers becomes more and more severe, leading to blue fingers. The skin can become atrophic, ulcerated or gangrenous. It’s important to note that the effects of vibration can vary significantly between individuals, with some being more susceptible to its biological effects than others. Therefore, the hidden costs of vibration are substantial, affecting not only individual health and well-being but also productivity and healthcare systems. Vibrations are structure killer Vibrations generate cyclic stresses in structures, contributing to material fatigue. Even if the stress from each vibration cycle is well below the ultimate strength of the material, the constant application of these stress cycles can result in microscopic cracks. Over time, these cracks grow larger, and eventually, they can lead to the failure of the structure. These cracks grow due to a process known as fatigue crack propagation. In each vibration cycle, the material at the crack tip is subjected to a stress cycle, causing a small amount of permanent deformation. This deformation extends the crack slightly. Cumulatively, over thousands, millions, or even billions of vibration cycles, these tiny extensions can cause substantial crack growth. This growth can compromise the structural integrity, leading to potential failure of the structure over time. Vibrations can also lead to the loosening of bolts, nuts, and washers in a structure. The cyclical nature of vibrations can induce relative motion between the bolt and the nut. This relative motion can gradually cause a bolt or nut to ”unwind,” leading to a loss of preload – the tension that holds the bolted joint together. Over time, this can result in the bolted connection becoming loose, known as vibrational loosening or self-loosening. Loose connections within a structure can compromise its stability and safety. Vibration can cause damage to non-structural elements such as grating, flashing, handrails, stairs, non-structural walls, and colourbond panels. Common issues include the loosening of grating connections, compromised effectiveness of flashing, fatigue and wear in handrails and stairs, cracking or detachment of non-structural walls, and metal fatigue in colourbond panels. Regular inspection, maintenance, and reinforcement of these elements are essential to ensure their stability and prevent potential failures. Financial aspects of vibrations The financial implications of vibration-related issues in industrial facilities are substantial and multi-faceted. Direct costs arise from the need to repair or replace machinery and structures that fail due to vibration-induced fatigue. Indirect costs are associated with production downtime, which can lead to lost sales and profits if suitable replacements or repairs are not readily available. Furthermore, the health implications of vibration on workers can translate into significant financial burdens. These include healthcare expenses, reduced productivity due to illness, and potential compensation claims in cases of long-term health effects. Therefore, businesses must balance the costs of implementing vibration mitigation strategies against these potential losses. Investment in proper maintenance, vibration monitoring, and control measures can often lead to significant long-term savings by preventing catastrophic failures and reducing health-related costs. The specifics of these costs can vary significantly depending on the particular industry, machinery involved, and extent of vibration issues. This is why engineers need to take vibrations seriously To effectively address vibration-related risks, it is crucial to partner with industry-leading experts who specialize in assessing and mitigating vibration problems. Experts offer holistic solutions for vibration-related challenges. They evaluate, analyze, and implement effective vibration control strategies. Stay updated with the latest advancements and solutions by following Mincka Engineering on LinkedIn. Together, let us create a safer, healthier, and more productive industrial environment by proactively managing the dangers of vibration.