3D printing has revolutionised advanced industries around the world, allowing engineers to manufacture highly specific components at a moment’s notice. From aerospace to automotive, and from medicine to mining, 3D printing has ushered in a new era of efficiency and development for highly technical businesses. Ready to lean into innovation for the long term? Let’s take a look at how this breakthrough is breaking new grounds in mining.

Rapid Prototyping

The ability to rapidly prototype specific components and equipment is a godsend to mining engineers. Testing assumptions in record timing cuts down on costly mistakes, increases efficiency, and propels innovation forward by putting advanced manufacturing capabilities in the hands of an on-site team. It’s a boom for individual mine sites, but the overall impact is being felt industry-wide.

Supply Chain Management.

Because 3D printing allows for many parts to be manufactured on-site, the reliance on ordering and shipping processes can be eliminated. This means reduced costs and increased efficiency as replacement parts may only take minutes to fabricate rather than weeks to arrive. Additionally, downstream costs related to inventory can be reduced as new parts are manufactured on demand.

Better Tools

As information and designs are collected over time, engineers and companies can design new intellectual property along the way. New tools can be developed and tested on the fly in response to the demands of any given task. When combined with Computerised Numerical Control machining these newly designed tools can disrupt processes long thought to be necessary in mining. Every application from industrial cutting, grinding, drilling, and polishing can be enhanced or performed using high-quality 3D printed materials.

On-Demand Protective Gear

Although not mining-specific, 3D printing allows for the bulk manufacture of personal protective equipment on-site. As new health and safety challenges emerge, it’s now widely accepted that the need for PPE is not going away any time soon. Equipment such as hard hats, hearing protection, protective eyewear, and respirator masks can all be 3D printed on-site, ensuring workers are equipped to continue their work in the face of the next public health challenges.

Immediate Knowledge

With the rise of 3D printing in mining, vast libraries of CAD designs are now available commercially. These libraries are growing constantly, creating a globally crowd-sourced knowledge base that can be purchased or shared for immediate use.

Eco-Friendly Materials

3D printing is surprisingly eco-friendly, requiring less overall energy consumption and commitment (there are no minimum manufacture requirements), and driving forward the use of sustainable additives and novel plastics. Many broader innovations are likely to spring from industrial 3D printing applications, making this innovation one of the most exciting and promising in sight.

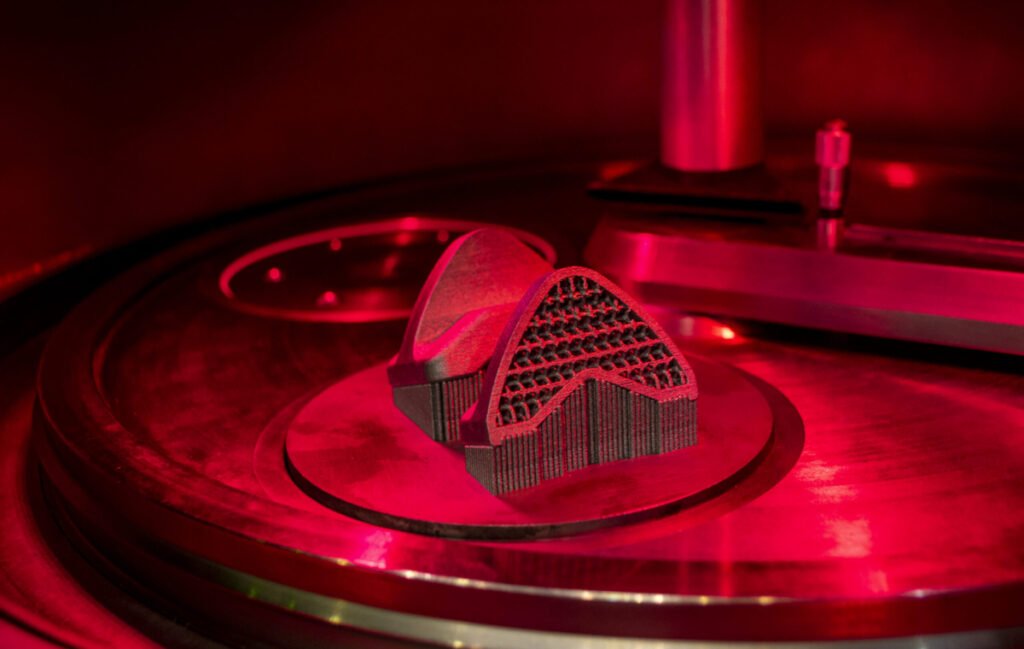

Mincka regularly uses 3D printing in the field, using it to create a range of engineering solutions for our clients. Our most common use case is in printing scale models for a better understanding of design outcomes and cross-section reviews.